MOQ: 10000 Pieces

Material: Aluminum Foil

Supply Ability: 300000 Piece/Pieces Per Day

Port: Dalian Or According To CustomersNeed

Payment Terms: L/C, T/T, PayPal, Western Union

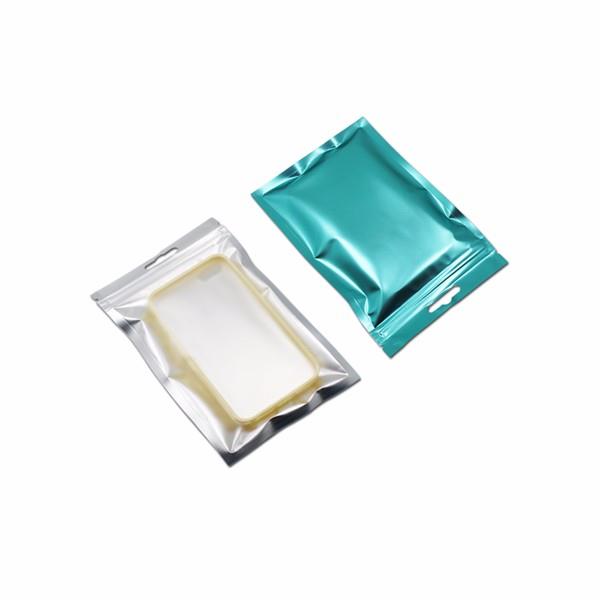

Product Name | Aluminum Foil Electronic Bag With Zipper |

Size | Customized |

Color | Customized |

Logo | Customized |

Material | Aluminum Foil |

Place Of Origin | Liaoning, China |

Advantages

1) Professional Flexible Packaging Manufacturers In China

2) Perfect & High Efficient Customer Service

3) Excellent Product Quality

4) Latest Production Lines To Ensure The Lead Time For Every Order

5) Advanced Testing & Facilities In Our Laboratory

6) FDA, SGS, ISO9001:2000

7) Strict Quality Control & Zero Quality Complaints

8) Fast Feedback On Every Customer's Request

Aluminum foil by shape can be divided into rolled aluminum foil and flaky foil. Aluminum foil deep processing of wool most of the roll-like supply, only a few handicraft packaging occasions only with flaky foil. Aluminum foil by the state can be divided into hard foil, semi hard foil and soft foil.

① hard foil: After rolling without softening treatment (annealing) of aluminum foil, without degreasing treatment, the surface of the residual Shantou. Therefore, the hard foil in the printing, laminating, coating must be done before degreasing treatment, if used for forming processing can be directly used.

② semi-hard foil: aluminum foil hardness (or strength) between the hard foil and the soft foil, usually used for forming processing.

③ Soft foil: After the rolling after full annealing and softened aluminum foil, the material is soft, the surface is not residual oil. At present, most areas of application, such as packaging, composite, electrical materials, are used in soft foil.

We have a production process for Aluminum Foil Electronic Bag With Zipper.

On the imported equipment, there is a heating roller, to be printed base material after the roll, so that the substrate can be heated to 50 ℃, and then into the first color printing unit. Substrate temperature is beneficial to the improvement of adhesion of printing inks and drying. After the ink, ink into the dryer, dryer temperature arrangement in a low-high-low form set, easy to quickly dry.