MOQ: 100 Rolls

Material: PET

Supply Ability: 1000 Rolls Per Day

Port: Dalian Or According To Customers’ Need

Payment Terms: L/C, T/T, PayPal, Western Union

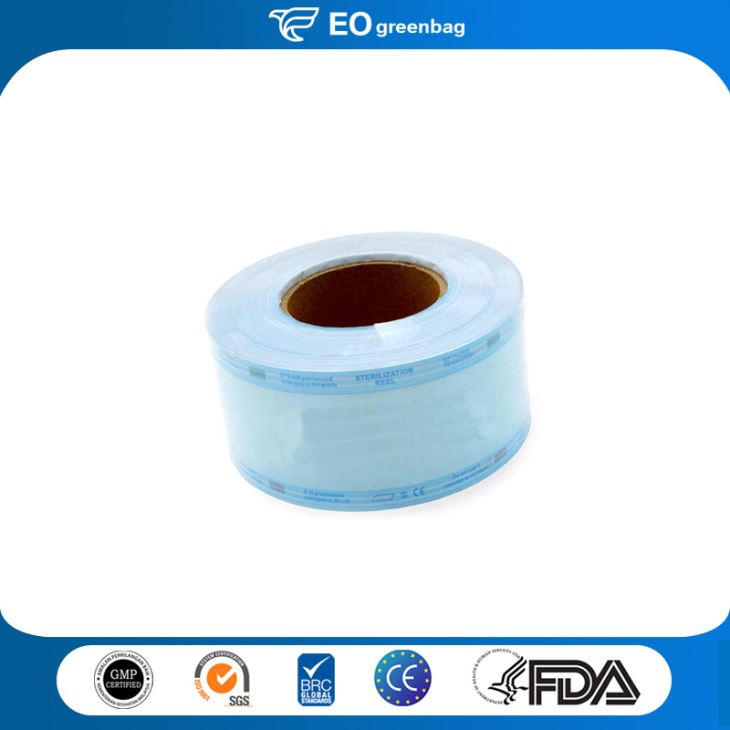

Product Name | Plastic Medical Bag On Roll |

Size | Customized |

Color | Customized |

Logo | Customized |

Material | PET |

Place Of Origin | Liaoning, China |

Advantages

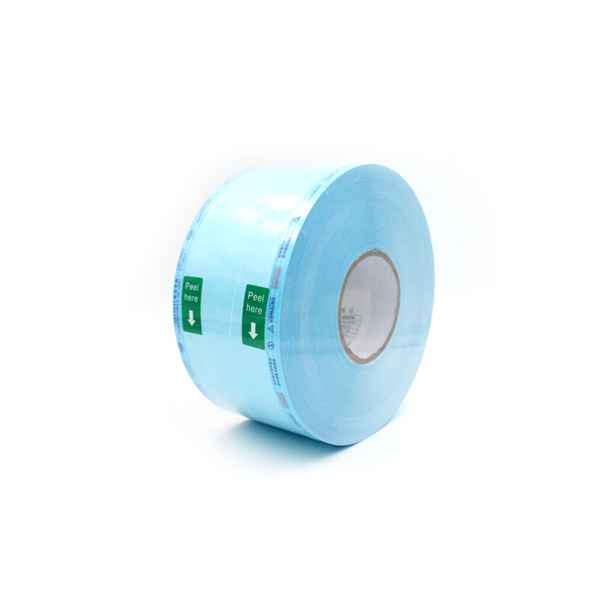

1.Usage: heat sealing sterilization roll apply to hospital, outpatient service antiseptic packing, laboratory articles antiseptic packing, family high temperature disinfection packing.

2.Sterilization method: Ethylene oxide, Steam, Gamma

3.Attentions:

(1) packaging bag at room temperature shelf life of 3 years, the storage period is 180 days after sterilization.

(2) check before use sterilization packaging bag seal integrity, product damage and disable.

(3) packaging bags for a one-time use, prohibit the use of two times.

PET (polyethylene terephthalate) is the abbreviation of polyethylene terephthalate in English. Is the most widely used beverage packaging materials today. Since pet can be easily cooled by means of rapid cooling method, the basic in amorphous state, high transparent, easy to stretch pet products, so as packaging materials pet can be made into two-way tensile packaging film, but also by the amorphous bottle embryo to obtain high-strength, high transparent tensile blow molding bottles, can also be directly extruded or blown into a non-tensile pet hollow container.

Pet Hollow container Especially stretch blow molding bottle, give full play to pet performance, have good display effect to content material, performance and cost compete with other hollow container. It is not only widely used in carbonated beverages, bottled water, spices, cosmetics, white wine, dried fruit candy and other products packaging, and after special treatment of hot filling bottles can also be used for fruit juice and tea beverage packaging.

Screen printing: thick ink Layer printing out of the pattern of three-dimensional strong, with the hands can touch the concave and convex feeling, suitable for high-end products of the surface printing, color expression is very good, multi-color overprinter more trouble, the surface requirements of the product is the rule of the plane or surface, there is a certain range of printing limitations.

In the substrate suitability, screen printing has a great advantage, especially in the amorphous plastic hardware and electronics and direct consumer goods industry, screen printing has been widely praised. However, there is no universal printing method in the world, screen printing is no exception. In the small area and irregular substrate surface of the industrialized printing field, screen printing encountered real trouble, this trouble has spawned the birth of the pad printing technology. It can be said that, although the transfer technology and screen printing are very different, they are involved in the industrial field but very similar.