MOQ: 1000 Pieces

Material: PVC

Supply Ability: 30000 Piece/Pieces Per Day

Port: Dalian Or According To Customers’Need

Payment Terms: L/C, T/T, PayPal, Western Union

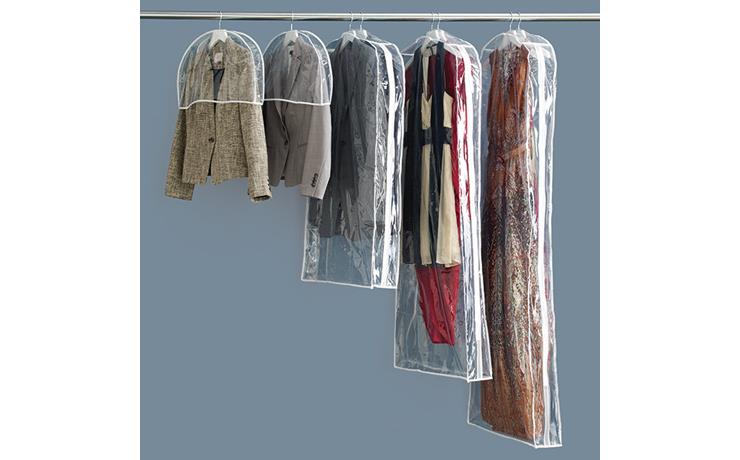

Product Name | Plastic Garment Bag With Pockets |

Size | Customized |

Color | Customized |

Logo | Customized |

Material | PVC |

Place Of Origin | Liaoning, China |

Advantages

1) Available Material: PVC Plastic

2) Size Accept: Any size you want.

3) Printing: Heat transfer printing.

PVC material is a kind of plastic decorative materials, the full name is polyvinyl chloride material, is to PVC resin as the main raw materials, add the right amount of anti-aging agent, modifier, etc., through mixing, calendering, vacuum molding and other processes from the material. PVC material has the characteristics of light weight, heat insulation, heat preservation, moisture-proof, flame-retardant and simple construction. is one of the most widely used decorative materials in plastic materials.

PVC Wall Stickers A lot of grades: Salt PVC resin (generally South Korea and Japan more), professional PVC film (harsh environment, such as use more, aircraft, ship use), PVC instant paste (the most common one, low price, wide range of use). Commonly seen in the domestic PVC instant paste material made of wall stickers, the quality of the difference is very obvious, the short-term surface is not seen, in the use of the process will show the difference, the brand better PVC materials can not easily fade aging, environmental protection.

We have a production process for Plastic Garment Bag With Pockets.

Thermal transfer technology According to the use of oil film varieties can be divided into sublimation transfer and hot embossing. Hot-Press transfer is mainly used plastic molding machine in the process of plastic molding fully using thermal pressure and thermal energy to achieve the printing pressure of a technical measure, and this thermal transfer technology in the transfer after the label concave inlay in the substrate surface interior.

Sublimation refers to the pressure and temperature under certain conditions, the solid material directly into the gaseous phenomenon, sublimation transfer is mainly refers to sublimation inks in the dye directly from the solid state into a gaseous process, and dye after sublimation and sublimation into solid substrate surface. Thermal transfer technology from printing can be divided into flat-screen printing, screen printing, convex printing, gravure printing ribbon printing and inkjet and so on. From the transfer can be divided into plastic film, plastic plate, ceramic, fabric and metal coating layer. From the substrate can be divided into heat transfer plastic film and thermal transfer paper.